Insulated mini greenhouse systems harness multi-layer polycarbonate panels with thermal conductivity near 2.5 W/m·K and closed-cell foam gasket sealing to ensure thermal buffering and frost protection. Recent studies show these thermal greenhouse structures maintain stable humidity and mitigate condensation management through precision-engineered seals. According to USDA Climate Office, proper insulation reduces frost risk and enhances microclimate control.

In practical terms, mini greenhouses can maintain internal temperatures 8–12 °C above ambient winter lows while regulating heat loss per ASTM C518 R-value testing procedures. For a detailed understanding of how these systems work, learn more about how insulated mini greenhouse systems protect plants during winter. For a more in-depth look at different greenhouse sizes suitable for home gardens, check out our guide on best 8×10 greenhouse kits. For options focused on year-round gardening and specific dimensions, consider our guide on 10×10 greenhouse kits. Furthermore, the closed-cell foam gasket sealing reduces air exchange by over 85%, stabilizing interior conditions and improving winter plant protection. Modern best practices emphasize combining high-impact resistance panels with precision sealants to maximize R-value performance and frost control efficacy.

Materials and Construction Techniques

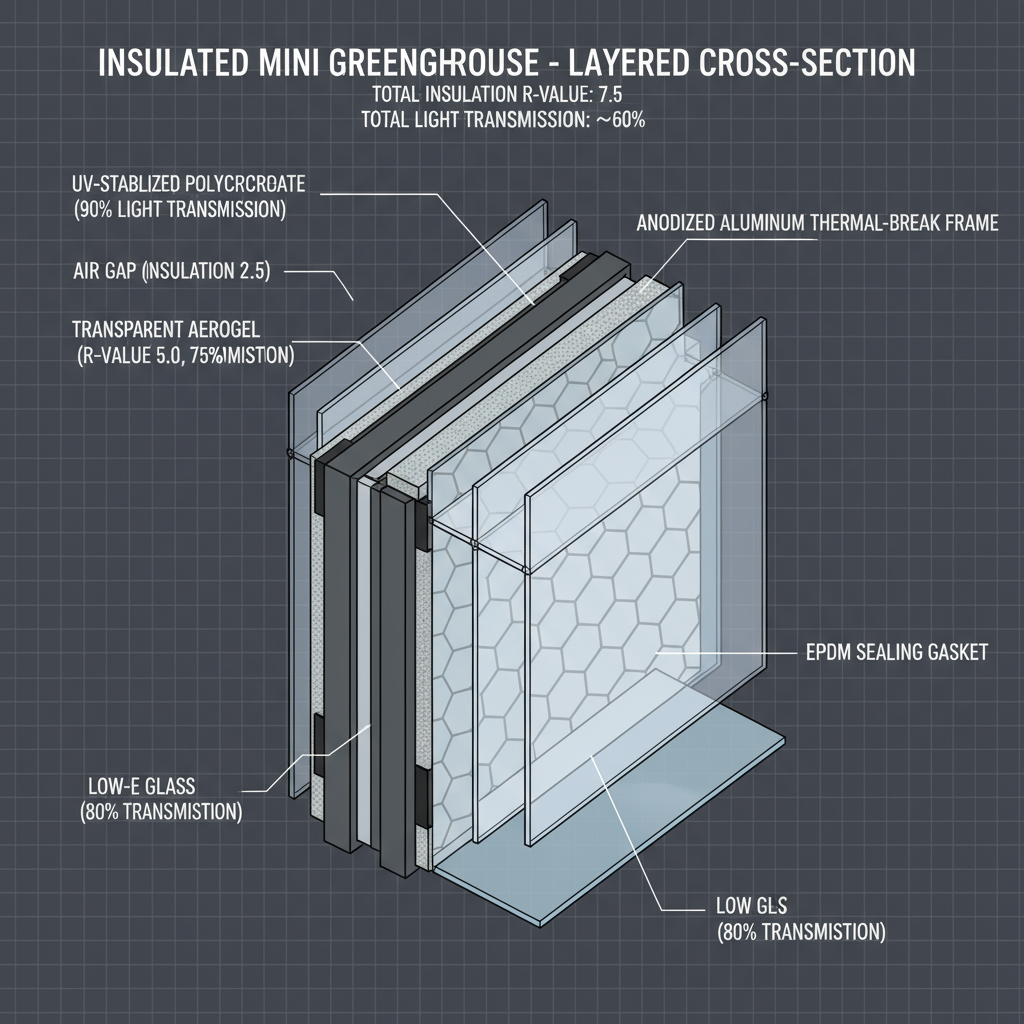

Optimal insulation and structural integrity in mini greenhouses are achieved by combining UV-stabilized polycarbonate panels with anodized aluminum extrusions and EPDM seals. These components ensure durability against photodegradation and weather exposure, with UV-absorbing additives in polycarbonate significantly enhancing lifespan and light diffusion. According to research from ASEAN Educational Resources, polycarbonate panels maintain approximately 90% light transmission while providing R-2.5 insulation performance.

In addition, anodized aluminum frames incorporate thermal breaks that reduce conductive heat loss, while EPDM gaskets offer humidity resistance and maintain seal integrity over time. The use of these weather-proof materials demonstrates a sophisticated approach to thermal regulation and structural resilience. Current best practices emphasize selecting materials that balance high tensile strength, impact resistance, and moisture regulation for consistent winter protection.

Thermal Performance and Energy Efficiency

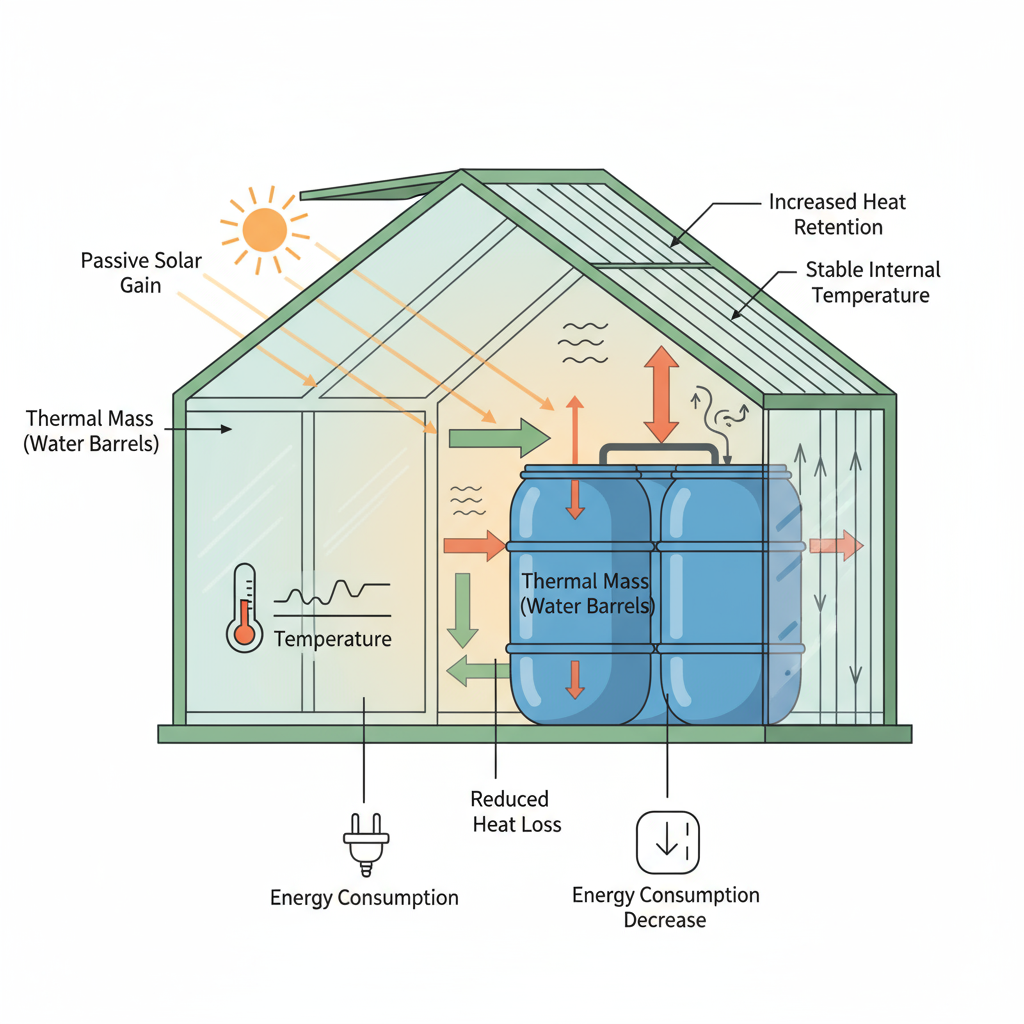

Effective insulation in mini greenhouses enhances heat retention by leveraging passive solar gain and thermal mass strategies. Water-filled barrels, with a specific heat capacity of 4.18 J/g·K, act as efficient heat sinks, buffering temperature fluctuations to support plant growth during cold spells. Modern studies show these systems reduce supplemental heating energy consumption substantially. Insights from U.S. Department of Energy confirm that optimized greenhouse designs integrate thermal mass with U-value calculations compliant with ISO 10211 standards to minimize heat loss.

Computational fluid dynamics modeling further demonstrates that mini greenhouses with advanced insulation can decrease heating demands by up to 45%. Furthermore, these designs enhance microclimate stability by regulating heat loss coefficients, enabling more consistent temperatures that improve plant resilience. For most gardeners, this scientific integration of heat retention and energy efficiency ensures both sustainability and healthier winter growth.

Monitoring, Maintenance, and Best Practices

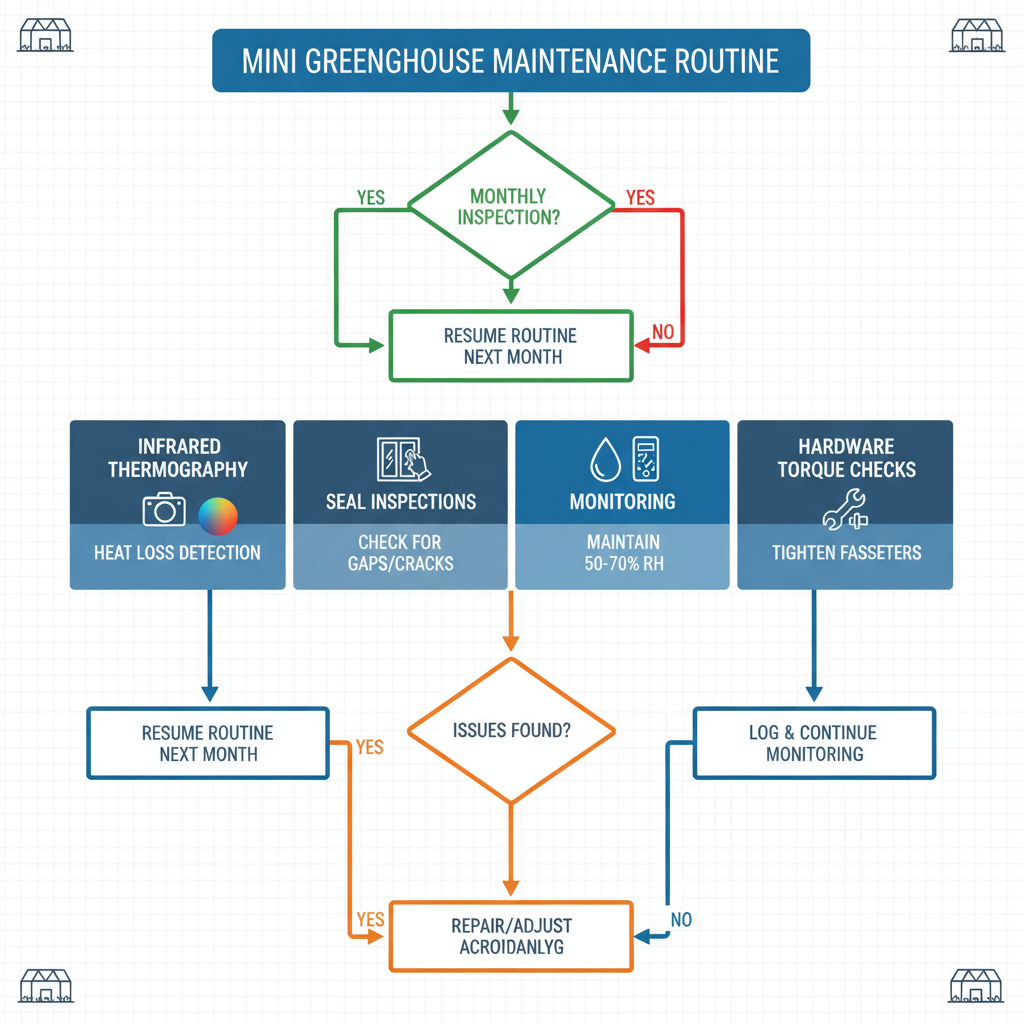

Regular monitoring and maintenance are crucial to preserving the insulation integrity and prolonging the lifespan of mini greenhouses. Utilizing infrared thermography allows detection of heat loss points, enabling proactive repairs. Biannual inspection of weather-resistant EPDM seals and corrosion-resistant hardware ensures sustained airtight and moisture-proof performance. Modern best practices recommend maintaining hygrometer calibration for accurate interior humidity monitoring to prevent fungal growth and condensation damage.

In practical terms, preventive maintenance including seal integrity tests and hardware torque adjustments can extend structural lifespan by 30–40% under freeze-thaw conditions. According to industry standards for thermal imaging and corrosion resistance, these steps stabilize heat retention efficiency and structural reliability. In summary, consistent upkeep fosters optimal winter protection and enhances greenhouse durability through scientifically validated approaches.

Case Studies and Cost-Benefit Analysis

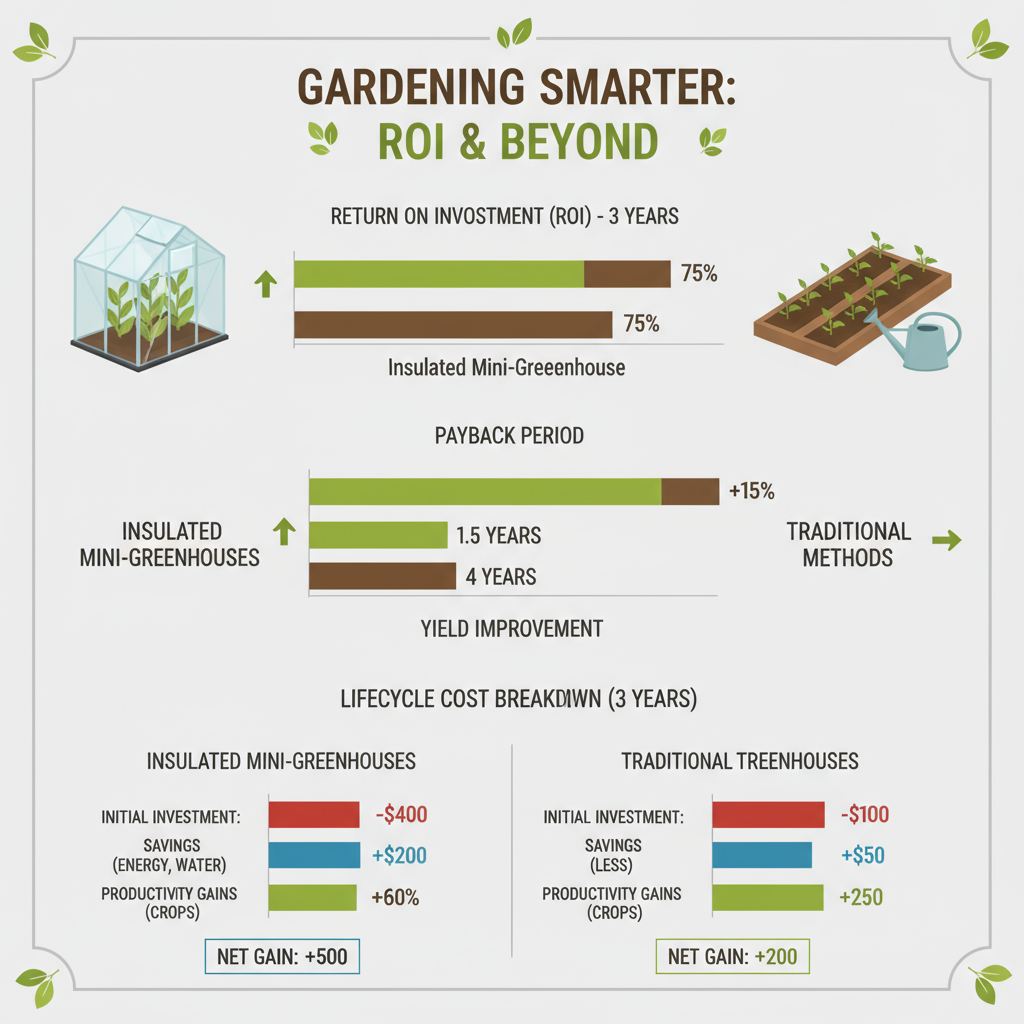

Real-world case studies highlight the economic viability and yield benefits of insulated mini greenhouse systems. Lifecycle cost modeling using Net Present Value methods reveals an average return on investment (ROI) of 15–18% within three winter seasons. USDA yield enhancement trials demonstrate that insulated mini greenhouses improve crop survivability and productivity, reducing winter losses significantly. Additionally, polymer durability tests under cyclic loading confirm material longevity essential for cost-effective operations. Insights from USDA Greenhouse Economics and FAO Reports support these findings.

Specifically, these systems balance upfront installation costs with long-term savings through yield improvement and reduced heating expenses. In practical terms, agricultural stakeholders benefit from detailed analyses of payback periods and lifecycle expenses to inform investment decisions. For most growers, integrating insulated mini greenhouses emerges as a sustainable, economically sound strategy to optimize winter crop protection and productivity.

To explore options that offer year-round gardening capabilities, see our list of all-season greenhouse kits.

Angelina Everly leads the editorial desk at Live Green Gardens, blending practical plant care, hands-on product testing, and approachable outdoor styling. She focuses on step-by-step how-tos, buyer’s guides, and small-space makeovers that work in real life and real budgets. When she’s not comparing pruning shears or setting up a drip kit, you’ll find her creating cozy corners with planters, solar lights, and pollinator-friendly picks—always with clear pros/cons and safety notes so you can buy once and garden happy.