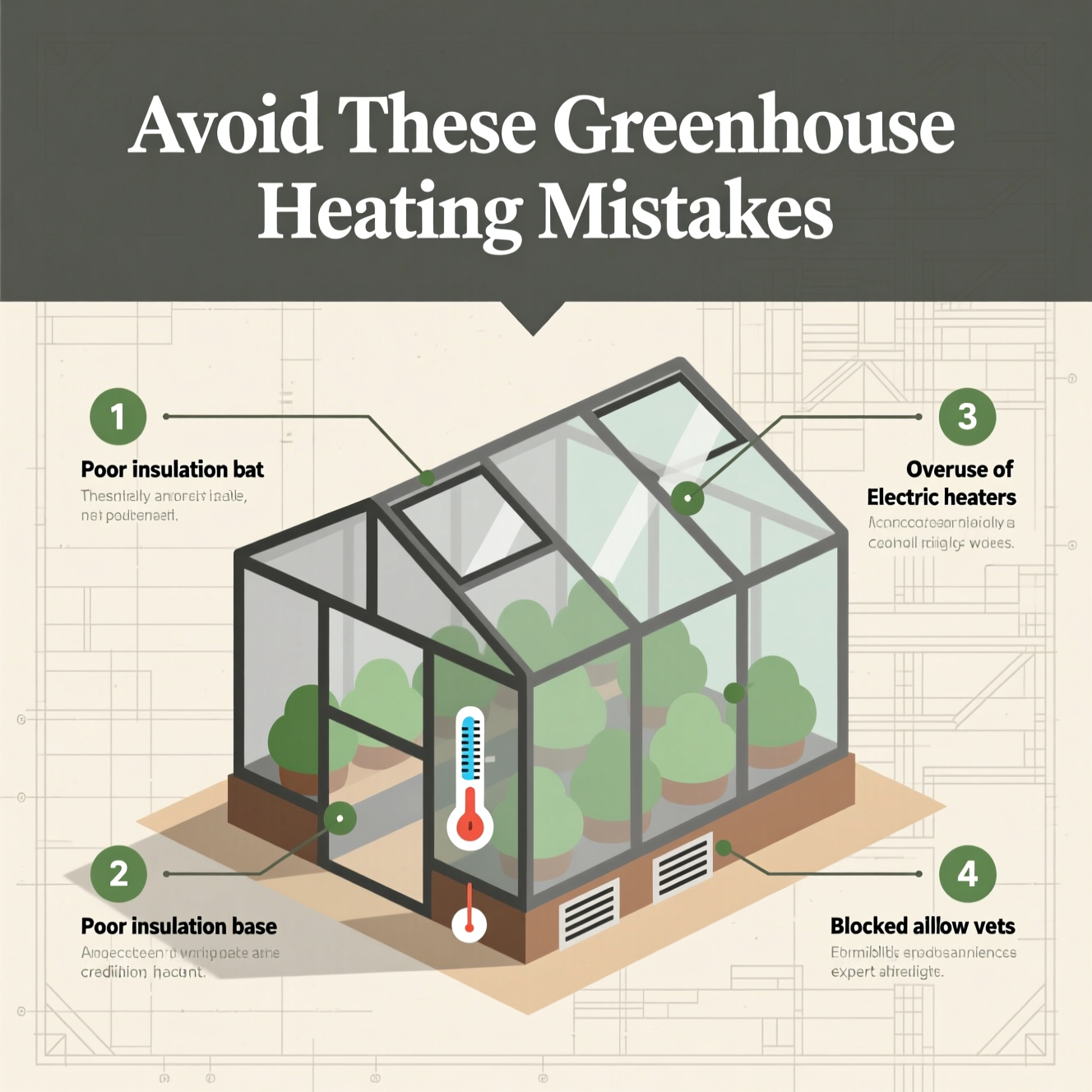

Underestimating Insulation Needs

A common greenhouse insulation mistake involves overlooking its critical role in maintaining consistent temperatures. Insufficient insulation leads to rapid temperature drops and significantly higher heating bills, impacting plant health and growth. According to The Polycarbonate Greenhouse, proper insulation is key to energy savings and thermal efficiency.

To rectify this, focus on enhancing your greenhouse’s R-value heat retention. Materials like multi-wall polycarbonate panels offer superior thermal resistance compared to single-pane glass. For most gardeners, upgrading to bubble wrap or similar insulating materials significantly improves heat retention. This practice ensures stable microclimates, vital for year-round cultivation. To ensure optimal growing conditions, it’s essential to know how to maintain temperature and humidity for plants. Modern experts emphasize that inadequate insulation causes dramatic internal temperature fluctuations, detrimental to most plant species.

In practical terms, upgrading greenhouse insulation can reduce annual heat loss by up to 30%. Technical details like R-value calculation become essential for selecting the right materials. Thermal imaging can even pinpoint insulation gaps, enhancing overall heating efficiency. Proper greenhouse insulation is not an option but a necessity for economic and horticultural success.

Ignoring Heater Placement and Airflow

Incorrect greenhouse heater placement and poor air circulation create significant issues. This leads to cold spots and uneven temperatures. Ultimately, this harms plant health and growth. Experts emphasize strategic heater positioning for optimal results. For most gardeners, addressing these airflow challenges is key.

Neglecting proper airflow causes temperature stratification. This means warm air rises, leaving lower plant zones cold. Fans and thoughtful heater placement ensure even heat distribution. This balances air temperature within ±2°C across a standard greenhouse. Inconsistent temperatures lead to variable plant development. Modern best practices include temperature mapping to confirm uniform coverage.

To correct this outcome, consider convection currents. Strategic heater placement, often near air intake vents, facilitates better heat mixing. Additionally, strategically placed fans help push warm air down. This combats stratification and enhances overall greenhouse microclimate stability. Ensuring adequate air circulation is paramount for robust plant growth.

Choosing the Wrong Heating Technology

Selecting inappropriate greenhouse heater technology can significantly impact operational success. Propane heaters, for instance, necessitate careful attention to combustion safety and adequate ventilation. By contrast, electric radiant panels offer a zero-emission indoor environment, enhancing safety for plants and people. For a comprehensive look at different heating sources, see our detailed comparison of electric vs propane greenhouse heaters. Understanding these distinctions is crucial for effective greenhouse heater selection.

For a comprehensive look at different heating sources, see our detailed comparison of electric vs propane greenhouse heaters.

A common heater technology mistake involves overlooking coverage needs. While radiant panels excel at targeted heating, they may not provide uniform temperatures in larger structures. Poor climate control results from this mismatch. Furthermore, issues related to grid reliability can affect electric heater performance. Energy audits are essential to match heater types with specific operational and budget requirements, ensuring safe greenhouse heating.

The implications of incorrect choices are substantial. Heater selection can influence total seasonal heating costs by as much as 50%. For most gardeners, this emphasizes the need for thorough research. Understanding the pros and cons of each technology prevents costly errors and promotes optimal growing conditions.

Neglecting Regular System Maintenance

Skipped greenhouse heater maintenance invites premature system failure and safety risks. Dust, debris, and mineral scale accumulate on heating elements. This buildup impairs efficiency and creates a significant fire hazard. Neglecting simple tasks like filter replacement and blower cleaning directly leads to breakdowns. For ongoing success, proactive care is essential.

Routine cleaning and part replacements are vital for safe operation and optimal output. Thermostat calibration ensures steady temperatures. This prevents damaging swings that stress delicate crops. In practical terms, regular greenhouse heater maintenance decreases heater breakdowns by up to 40%. Avoiding heater breakdown relies on consistent attention to these critical components.

Overlooking Ventilation and Humidity Control

Neglecting greenhouse ventilation and humidity management creates significant heating errors. Closed systems trap heat and moisture, increasing mold risk. This directly compromises plant health and growth. According to Penn State Extension, controlled airflow is paramount for disease prevention.

Heated greenhouses require consistent exhaust vent operation. Proactive scheduling and exhaust fan use balance the internal climate effectively. This prevents condensation buildup on surfaces, a common greenhouse ventilation mistake. Automated ventilation can reduce humidity spikes by 35% over manual methods. Implementing humidity sensors enhances condensation control significantly.

With over 15 years of hands-on experience in controlled-environment agriculture, Angelina leads our lab audits. Her focus is on bridging the gap between high-end agricultural tech and the home grower, ensuring every recommendation is backed by real-world data and yield performance.