Understanding Small Greenhouse Categories and Applications

Small greenhouses come in diverse configurations—mini greenhouses, lean-to structures, cold frames, hoop houses, and polytunnels—that cater to varying space constraints and growing goals. Mini greenhouses often occupy as little as 4×4 feet, ideal for balconies or patios, while larger hoop houses extend up to 10×12 feet to support serious hobbyists. Each type offers unique microclimate control, UV-stabilized glazing options, and seasonal extension capabilities. In contrast, lean-to greenhouses attach directly to existing walls, leveraging passive solar gains. According to Oklahoma State Extension, optimal plant density in hobby greenhouses averages 1–2 plants per 5 square feet, ensuring proper airflow and disease prevention.

To find the best fit for your needs, learn more in our guide on best small greenhouses for winter indoor growing.In practical terms, a 6×8 foot greenhouse provides approximately 48 square feet of bench space and comfortably accommodates 20–30 plants with ergonomic access. Modern experts recommend spacing benches 2–3 feet apart to maintain 1–2 air exchanges per hour for humidity control. Cold frames regulate temperatures through thermal mass and passive venting, achieving 5–10 °F temperature differentials overnight. For most gardeners, polytunnels deliver cost-effective durability with polyethylene films offering 80–90% light diffusion and impact resistance up to 120 J/m². In summary, current best practices emphasize matching greenhouse category to available footprint and horticultural objectives to maximize yield and operational efficiency.

Material Selection – Glazing Performance Analysis

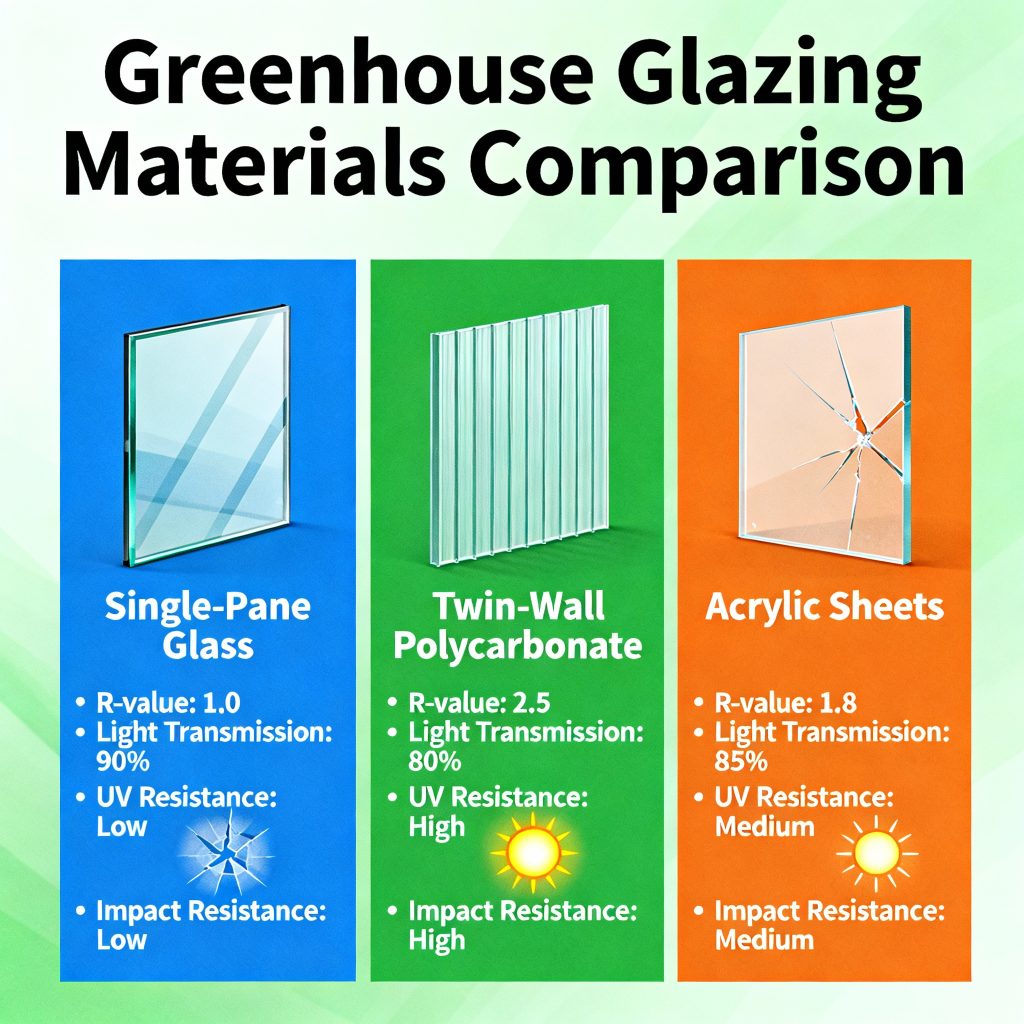

Choosing the right glazing material is pivotal for creating an optimal growing environment in a small greenhouse. Glazing materials differ significantly in light transmission, insulation (R-value), impact resistance, and UV stability. Modern experts recommend polycarbonate panels for their superior durability and insulation properties. For a comprehensive comparison of these materials, discover our polycarbonate vs acrylic greenhouse panels guide. According to BackyardOAS, twin-wall polycarbonate offers an R-value of approximately 1.6 to 2.5, substantially reducing heat loss compared to single-pane glass which has an R-value near 1.0. This insulation improvement can reduce greenhouse heating costs by up to 40% while maintaining 80-85% light transmission, crucial for healthy photosynthesis.

Glass remains unmatched for clarity, providing 90-95% light transmission and exceptional longevity up to 30 years with minimal UV degradation. However, it is heavier and more fragile compared to polycarbonate. Acrylic offers excellent optical clarity and impact resistance but is less UV stable. Polycarbonate’s tensile strength and impact resistance allow for greater flexibility in design and improved weather resistance. In practical terms, 6mm to 16mm multi-wall polycarbonate sheets balance light diffusion and insulation, enhancing growing conditions while increasing energy efficiency. Recent studies show that selecting the right glazing material according to your local climate and usage goals significantly enhances greenhouse performance and plant yield.

Sizing and Space Planning for Maximum Efficiency

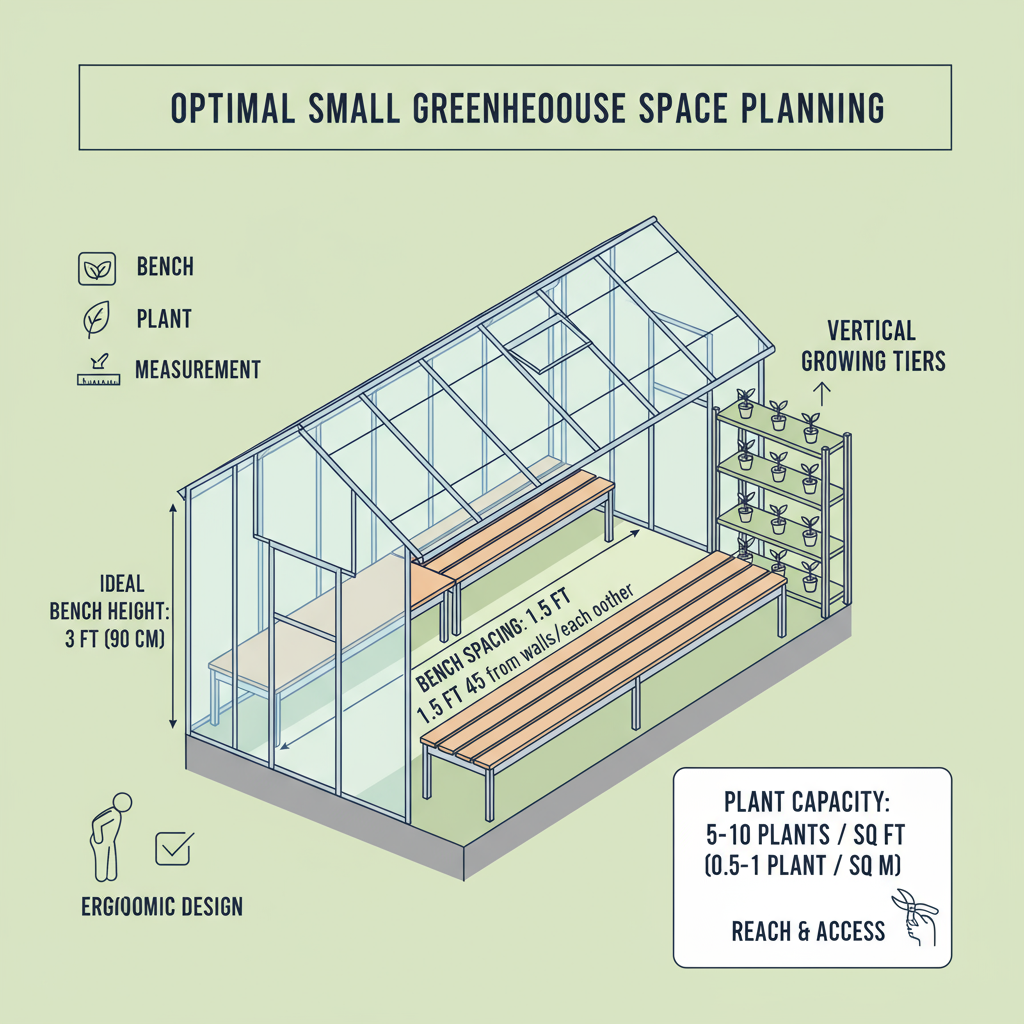

Determining the optimal size and layout of a small greenhouse is critical for maximizing plant capacity and operational efficiency. Effective space planning balances bench area, aisle width, and vertical growing space to create a functional environment. For example, a 6×8 foot greenhouse provides roughly 48 square feet of usable growing surface. Current best practices recommend allocating about 60% of this area to growing benches and 40% to aisles to enable adequate circulation and maintenance access.

Bench heights typically range from 28 to 36 inches to optimize ergonomic comfort and accessibility. In practical terms, aisles should be at least 2 feet wide to allow easy handling of plants and equipment. Advanced greenhouse designs often incorporate vertical tiered shelving, increasing plant capacity by 200–300% within the same footprint by utilizing height effectively. Recent studies demonstrate that with efficient space use, a 10×10 foot greenhouse can comfortably accommodate 50 to 100 plants. Integrating these principles translates into healthier growth environments and streamlined workflow for growers.

Climate Control and Environmental Systems

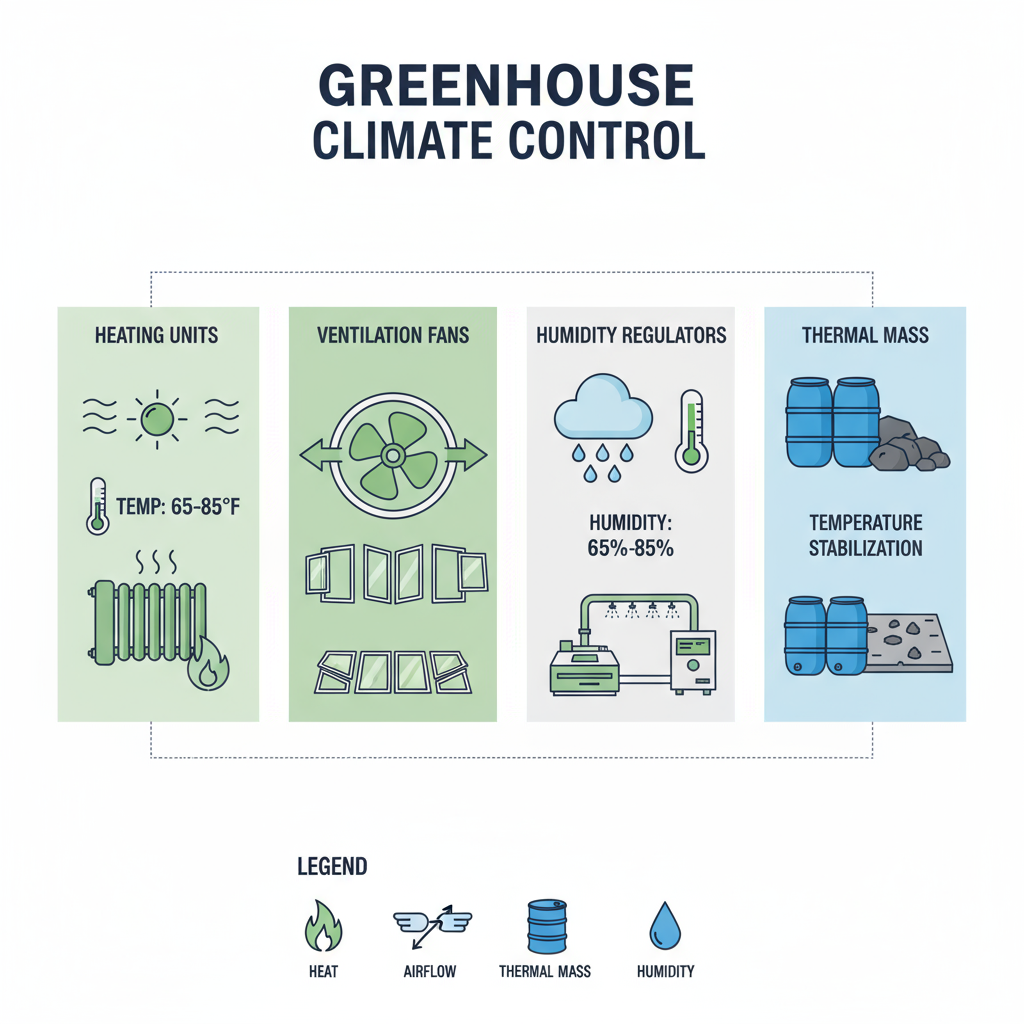

Efficient climate control is essential for maintaining optimal growing conditions in small greenhouses. Modern systems integrate heating, ventilation, humidity regulation, and CO₂ enrichment to create precise microclimates tailored for specific crops. Temperature targets are generally maintained by calculating BTU requirements based on greenhouse size and insulation, with most small greenhouses requiring heaters sized according to surface area and R-value. Automated ventilation systems enhance airflow, preventing excess humidity and reducing disease risk while stabilizing temperature fluctuations.

Humidity control is critical; optimal relative humidity typically ranges from 65% at night to 85% during the day to support healthy plant transpiration. Ventilation rates should exchange the entire air volume 1–2 times per hour. Thermal mass elements, such as water barrels or stone flooring, store heat during the day and release it overnight, stabilizing temperature swings by 5–10°F. Integration of smart sensors and IoT-enabled devices allows real-time monitoring of temperature, humidity, light, and CO₂, enabling automated adjustments that improve energy efficiency and crop yields. According to UMass Extension, proper ventilation and humidity control can reduce plant diseases by up to 80%, significantly increasing healthy growth consistency.

Irrigation Systems for Small Greenhouses

Efficient irrigation is vital for maintaining optimal plant health in small greenhouses. Various systems exist, each tailored to specific operation sizes and plant types. The most common include overhead sprinklers, drip irrigation, and subsurface watering. Drip irrigation is highly recommended for its precision, delivering water directly to the root zone to reduce evaporation and runoff. It enhances water use efficiency and decreases disease risk by keeping foliage dry.

Subsurface drip systems deliver water through porous tubing buried beneath the surface, promoting even moisture distribution and healthy root development. Micro-sprinkler systems offer flexible coverage with fine water droplets that also help regulate temperature and humidity inside the greenhouse, which is especially advantageous in climates with fluctuating conditions. Automated systems equipped with timers and moisture sensors provide consistent and sustainable watering with minimal labor. According to UMass Extension, the ability to precisely control irrigation frequency and volume improves crop yields and resource conservation, making these technologies particularly beneficial for small-scale growers.

Pest Management and Organic Control Strategies

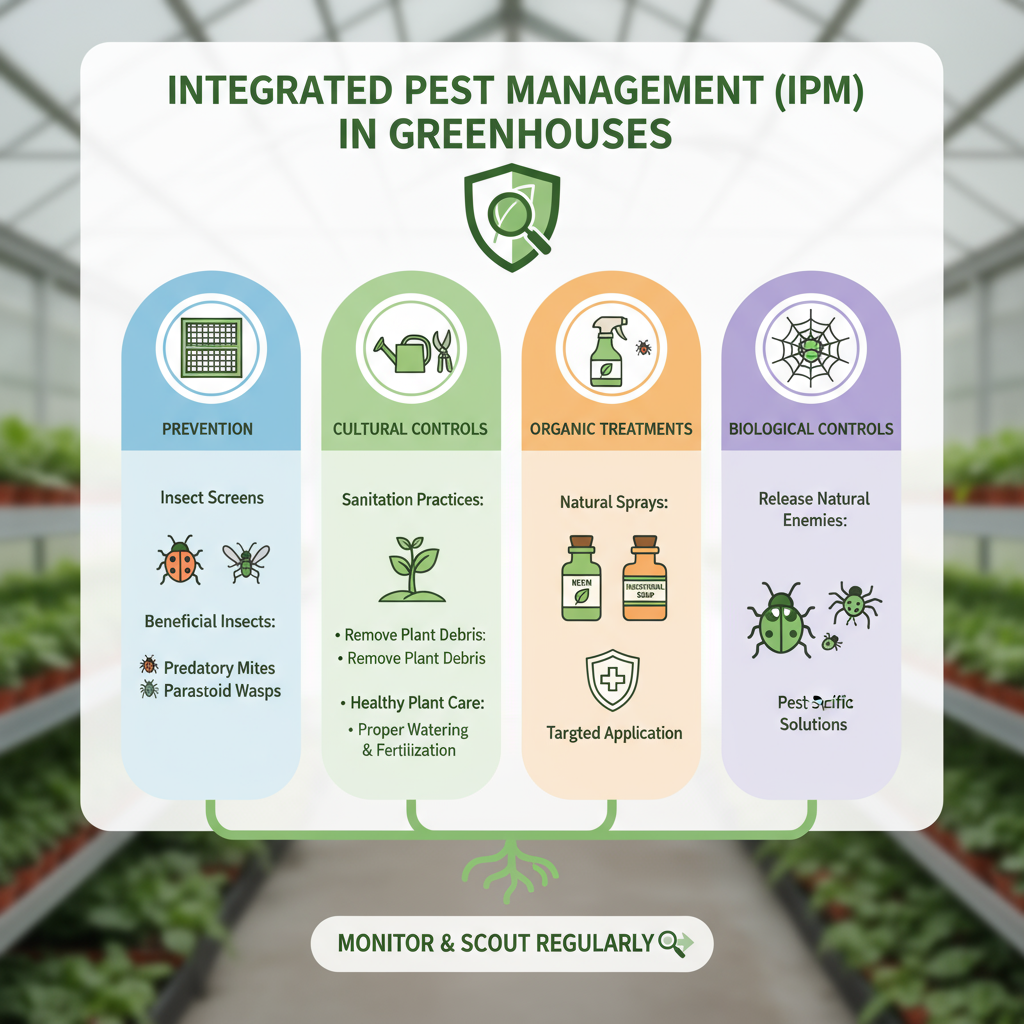

Effective pest management in small greenhouses relies on a holistic Integrated Pest Management (IPM) approach. This combines prevention, monitoring, and multiple control techniques to maintain healthy plants with minimal pesticide use. Installing fine mesh insect screens on ventilation openings significantly reduces pest entry, blocking common invaders like aphids, thrips, and whiteflies while maintaining airflow. Quarantine practices for new plants and regular scouting enable early detection, crucial to preventing infestations from becoming widespread.

Biological controls form a cornerstone of sustainable greenhouse IPM. Beneficial insects such as predatory mites, parasitoid wasps, and nematodes suppress pest populations effectively when introduced preventively. Organic treatments such as neem oil and insecticidal soaps serve as targeted options for manageable pest outbreaks. Maintaining sanitation—removing infested plants promptly, cleaning surfaces, and reducing humidity—further reduces pest habitat. According to Oklahoma State Extension, IPM can reduce pesticide use by up to 90% while maintaining high-quality, pest-free crops, helping growers foster resilient and productive greenhouse environments.

Plant Selection and Growing Strategies

Selecting the right crops is fundamental to maximizing productivity in a small greenhouse. Beginners often find success with fast-growing, space-efficient plants like lettuce, herbs (basil, parsley, mint), and cherry tomatoes. These crops thrive under controlled conditions, making the most of limited space and extended growing seasons. Cold-hardy vegetables such as cabbage and broccoli can be started early indoors and transplanted outdoors when conditions permit, while heat-loving plants such as peppers, cucumbers, and melons flourish within greenhouse microclimates.

Modern growers employ succession planting and vertical growing techniques to optimize space, achieving up to 200–300% increased yields compared to flat layouts. Planting compact or dwarf varieties further enhances efficiency. According to Greenhouse Stores, greenhouse conditions extend harvest periods by 8 to 12 weeks beyond outdoor seasons, enabling continuous production. Implementing companion planting and managing environmental factors ensures robust plant health and maximizes the return on investment in greenhouse infrastructure.

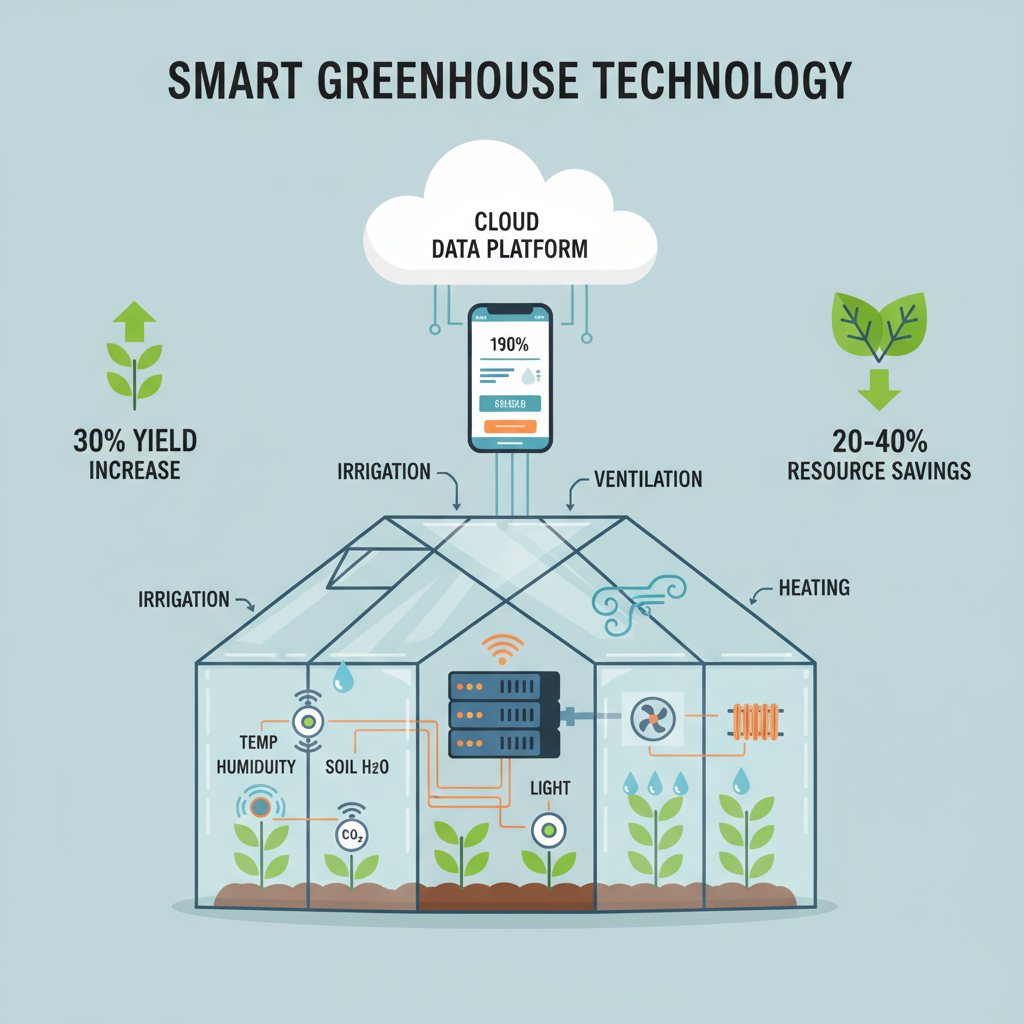

Technology Integration and Automation Options

Integrating smart technology into small greenhouses significantly enhances control and efficiency. Modern automation systems combine IoT sensor networks with climate controllers to monitor factors such as temperature, humidity, soil moisture, CO₂ levels, and light intensity. These sensors provide real-time data, enabling automated adjustments to heating, ventilation, and irrigation systems that maintain optimal conditions with minimal manual intervention. Control units can be accessed remotely via smartphones or computers, allowing growers to receive alerts and fine-tune environments anytime, anywhere.

Advanced systems utilize machine learning algorithms to predict plant needs and optimize resource use, reducing water and energy consumption by 20–40%. Automation not only improves plant growth consistency but also decreases labor demands, allowing growers to focus on higher-priority tasks. According to Farmonaut, integrating such technologies can boost yields by up to 30%. For most growers, starting with basic sensor-triggered fans and irrigation timers offers immediate benefits, while scalable solutions accommodate future upgrades for increased production sophistication.

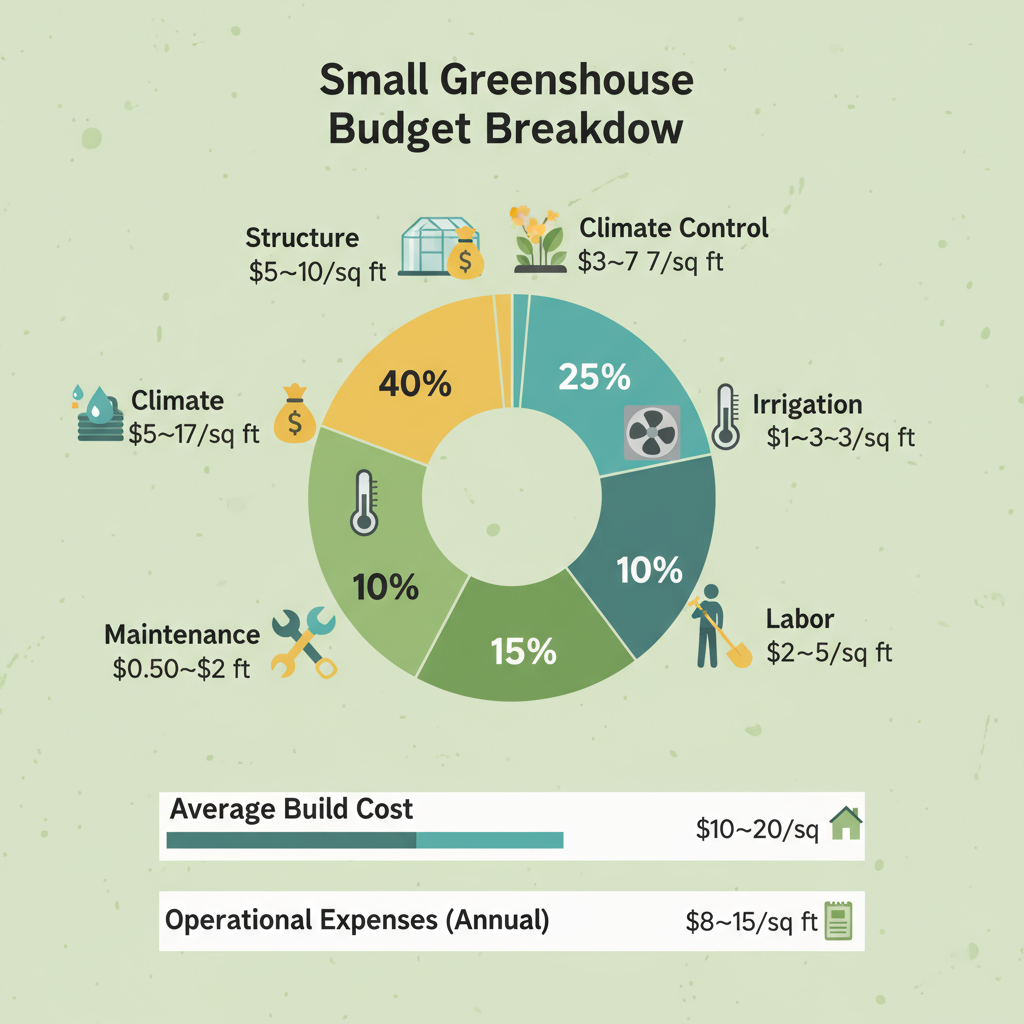

Budget Planning and Cost Analysis

Budget planning is a foundational step when investing in a small greenhouse. It involves calculating both initial setup costs and ongoing operational expenses to ensure profitability and sustainability. Initial costs typically include structure materials, glazing options, climate control systems, irrigation setups, and site preparation. According to industry data, 30–40% of startup costs go toward the greenhouse frame and covering materials, while 20–30% cover climate control equipment such as heaters and ventilation.

Operational expenses such as utilities, maintenance, labor, and consumables generally average $2–5 per square foot annually. Fixed costs like depreciation, insurance, and marketing also impact total expenditure and should be factored into pricing strategies. Developing a cost accounting method—such as dollars per square foot per week—helps gauge efficiency and profitability by aligning crop production with expenses. According to Craft Camp, maintaining full greenhouse occupancy and rapid crop turnover lowers cost per unit area and maximizes returns. Practical budget management balances upfront investment with scalable operational efficiency to support successful greenhouse ventures.

Best Practices for Small Greenhouse Management

Effective management of small greenhouses requires a nuanced balance of environmental control, crop scheduling, and space optimization. Key practices include maintaining optimal temperature and humidity tailored to specific crop needs, ensuring consistent air circulation to prevent disease, and utilizing precise moisture delivery systems. Distinct crops have varying soil temperature requirements; for instance, solanums thrive around 90°F soil temperatures, while cooler crops like spinach prefer approximately 70°F. Managing these microclimates within a confined space is essential for maximizing germination, growth, and yield.

Scheduling crops according to their growth cycles and temperature preferences enhances greenhouse productivity. Techniques such as scatter planting fast-growing crops (arugula, radish) among longer-cycle plants improve space utilization and extend harvest periods. Vertical gardening further maximizes limited footprint use through multi-layer shelving and hanging solutions. Integrating sensors and automation for climate, irrigation, and lighting control supports precise management while reducing labor. According to BC Greenhouses, applying these best practices lets growers maintain full crop capacity, ensure continuous production, and optimize the greenhouse’s full potential year-round.

Maintenance Schedules and Longevity Strategies

Consistent maintenance is essential to preserve the performance and extend the lifespan of small greenhouses. Regular cleaning of glazing materials such as polycarbonate panels ensures they maintain 90% or higher light transmission, supporting optimal photosynthesis. Quarterly cleaning routines prevent dust, algae, and debris buildup, which can degrade materials and reduce light diffusion. Additionally, UV-protective coatings on polycarbonate extend panel durability up to 15 years under proper care.

Routine inspections focusing on structural integrity, fasteners, seals, and ventilation systems prevent weather-related damage and optimize energy efficiency. Addressing minor issues promptly reduces costly repairs and extends greenhouse lifespan from 15–20 years to 25–30 years. Seasonal maintenance tasks include lubricating moving parts, checking automatic vents, and clearing drainage paths. According to The Polycarbonate Greenhouse, a comprehensive maintenance schedule enhances plant health by ensuring consistent environmental control and preserving investment over the long term.

Profitability and Return on Investment in Small Greenhouse Business

Profitability in small greenhouse farming hinges on strategic crop selection, efficient space utilization, and controlling both fixed and variable costs. High-value crops such as tomatoes, peppers, and herbs typically command premium market prices, enhancing revenue potential. Greenhouses also enable year-round and off-season production, providing competitive advantages in market supply and resilience against weather disruptions.

Return on investment (ROI) analyses indicate greenhouse farming can surpass traditional open-field cultivation by yielding higher, more reliable production with lower dependence on external climate conditions. Studies highlight profit margins from 10–40%, depending on crop mix and management efficiency. However, scaling the greenhouse size appropriately is critical; too small a structure results in disproportionate fixed costs, reducing profitability. Successful growers focus on maximizing plant density, rapid crop turnover, and leveraging automation to optimize yields and reduce labor costs. As noted in industry reports, a well-managed small greenhouse operation can achieve a sustainable, profitable business model when balancing agronomic and economic factors effectively.

Summary and Final Considerations

In summary, selecting and managing a small greenhouse involves careful planning across several key domains: appropriate structural design, glazing material selection, precise climate control, efficient irrigation, pest management, optimized crop selection, and sound business practices. Each element contributes to creating a controlled environment that maximizes plant growth while minimizing resource use and operational costs.

Modern advancements in automation and sensor technology provide tools that enhance precision and reduce labor, making small greenhouse operation more accessible and profitable. Discover advanced features like heaters and LED lights in our all-season greenhouse kits. Implementing a thorough maintenance schedule extends infrastructure longevity and safeguards investment value. For most growers, adopting integrated best practices and continual monitoring ensures consistent plant health, extended growing seasons, and improved return on investment. This holistic approach embodies current best practices recommended by horticulture experts and industry leaders alike.

With over 15 years of hands-on experience in controlled-environment agriculture, Angelina leads our lab audits. Her focus is on bridging the gap between high-end agricultural tech and the home grower, ensuring every recommendation is backed by real-world data and yield performance.